Video uploaded, no audio so make sure you have your notes handy!

PDF to follow soon, let me know how you get on with this video to help shape future tutorials.

Ed

Untitled from warderoid on Vimeo.

Showing posts with label CNC. Show all posts

Showing posts with label CNC. Show all posts

Wednesday, 26 October 2011

Wednesday, 12 October 2011

CNC Queue

To alleviate some of the confusion of getting on the CNC mill that we encountered last year, a list has been taped onto the side of the machine.

Its really quite simple - get your work ready for milling, add your name to the list and wait your turn!

Simply thinking of using the mill for your project doesn't grant you use of the machine when you want it!!

The process goes something like this:

Get 2D / 2D data ready

Run the job through Rhino CAM

Get the simulation animation checked

Put the posted gcode file onto the PC next to the mill

Source and prep your material

Add your name to the list

Wait your turn!

Don't forget that several courses use the CNC mill to realise their work, so it may take a while for your turn to come around.

Any one job can take a long time to complete, let alone a list full of them! We can only run the machine 8 hours per day, so carefully consider your time and the direction of your project before using the mill.

Its really quite simple - get your work ready for milling, add your name to the list and wait your turn!

Simply thinking of using the mill for your project doesn't grant you use of the machine when you want it!!

The process goes something like this:

Get 2D / 2D data ready

Run the job through Rhino CAM

Get the simulation animation checked

Put the posted gcode file onto the PC next to the mill

Source and prep your material

Add your name to the list

Wait your turn!

Don't forget that several courses use the CNC mill to realise their work, so it may take a while for your turn to come around.

Any one job can take a long time to complete, let alone a list full of them! We can only run the machine 8 hours per day, so carefully consider your time and the direction of your project before using the mill.

Thursday, 29 September 2011

Paneling tools

Elo!

Had some fun with the paneling tools plug it - without getting overly fancy, using a custom paneling grid on a surface - I was able to create an interesting surface pattern on 12mm ply!

A simple surface just over 200mm square, rebuilt with 6 u and v points, slightly edited to give depression and curvature.

The paneling grid was set to 15 in both U and V, for a rather densely populated surface, the custom shape was a simple paraboloid.

I opted for ply as it will illustrate the contours more so than acrylic would.

Thanks for looking :)

blobby thing

This was an intersting project, by the time I got around to starting it!

The model is a prototype for an instiliation, the model would be then moulded and cast in cermaics.

The data was from Rhino, and the model - being deeper than my CNC Mill could handel, was split into 4 and 3D printed on the Zcorp 510.

Once printed, they were Infiltrated with resin and joined, filled, sanded, 2K primed and sprayed a gloss white.

There wasnt one - but two! It took 3 days, mostly spent sanding, fillig, priming, sanding, filling, priming, sanding, filling priming - you get the picture. All this whilst trying to opperate a workshop with MA students running around!

Overall I was pelased with the outcome - its been a while since I used alot of the finishing skills I had supposedly aquiered at Curvature Group!

Overall I was pelased with the outcome - its been a while since I used alot of the finishing skills I had supposedly aquiered at Curvature Group!

The model is a prototype for an instiliation, the model would be then moulded and cast in cermaics.

The data was from Rhino, and the model - being deeper than my CNC Mill could handel, was split into 4 and 3D printed on the Zcorp 510.

Once printed, they were Infiltrated with resin and joined, filled, sanded, 2K primed and sprayed a gloss white.

There wasnt one - but two! It took 3 days, mostly spent sanding, fillig, priming, sanding, filling, priming, sanding, filling priming - you get the picture. All this whilst trying to opperate a workshop with MA students running around!

Overall I was pelased with the outcome - its been a while since I used alot of the finishing skills I had supposedly aquiered at Curvature Group!

Overall I was pelased with the outcome - its been a while since I used alot of the finishing skills I had supposedly aquiered at Curvature Group!

Labels:

3D printing,

CNC,

Feature,

Installation,

Machining,

Pattern,

Rhino,

Spraying

Sunday, 24 October 2010

3D printing Bandi Japan

http://www.youtube.com/watch?v=6bgfbteTLfY&feature=related

Mental video

I think we should adopt their work cloths

Mental video

I think we should adopt their work cloths

Labels:

3D printing,

Case Study,

CNC,

Feature,

General,

Machining,

Software,

tutorial,

Video

Wednesday, 20 October 2010

TCT Live 2010

Woop what a day - most spent in a car but some was spent at the awsome TCT live in Coventry.

Check out the Set on FlickR

Not much has changed from last year, machines have gotten smaller still and resolutions are getting higher. Things are getting cheeper but still out the reach of us poor people. :(

Labels:

3D printing,

Case Study,

CNC,

Digitising,

Engraving,

Feature,

General,

Lasers,

Machining,

Software

Monday, 4 October 2010

Solidworks more like solid wtf how do you get this to work?!

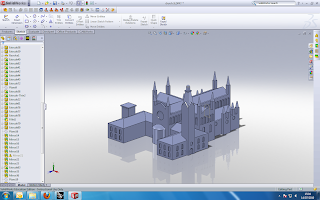

So yeah new year new software installed - we have an academic licence of Solidworks and CAMWorks - here's to hoping you already know how to use them!

Solidworks is pretty hot - I have been playing with it for a month or two now and getting the hang of it more, the more I use it. I actually really like it - it feels more intuitive than Rhino - in fact I barely open rhino any more other than drafting for the laser.

CAMWorks on the other hand though is something else - even getting the thing to load and find the licence is something like voodoo.

It should be a great product that seamlessly links 3D solid modeling with CAM and our Mill - so far its just making nice 3D digital models with no cam any time soon.

What this post was meant to be about....

I did manage to get a few models 3D printed here is my favorite!

Yes, it is a pink cathedral

Labels:

3D printing,

Case Study,

CNC,

Feature,

General,

Machining,

Software,

Solidworks

Wednesday, 7 July 2010

Bartlet Architecture Final Show UCL

Walking from Waterloo to UCL took just over an hour - but we got to see alot of London's back streets that would have been missed if we took the tube. The day was hot despite staring out with rain, and not taking the most direct rout at times just made things worse. Anyway - by 2:30 we had made it, and the courtyard of UCL was a little sancuary in the middle of hell that was london, quiet and calm, we were met with this.

In the right place then.

The show was pretty large accutally, spanning several rooms with a range of work in each. Models were everywhere which was a plus for me - and they were getting alot of attention from everyone else in the gallery.

To go with the countless models were collections of artwork which as an outsider I coulnt see the relevence to an Architecture degree show but they were stunning none the less - very sci fi.

The models on show had a range of technologies applied to them - predominently Dprinted with elements of lasercut acrylic. I spoke toone of the students on hand and asked about the software used to create such generative forms. They all get introductions into Rhino, Solidworks, Studio MAX - even google sketchup is used extensivly. He also explained that they build several models digitally - some for specification and also some specifically for the use of prototyping technologies. All models are brought and payed for at a little above cost.

Overall the day was great and well worth the treck accross London town to get there! The level of work - and the quality and extensiveness of the 3D prints was a great thing to witness!! Some of the aplications were questionable, such as a printed landform, but over all the applications were very generative and testament to their skills on CAD. Some of the details were very fine and bridging[from my persective] the gap between technology and art.

In the right place then.

The show was pretty large accutally, spanning several rooms with a range of work in each. Models were everywhere which was a plus for me - and they were getting alot of attention from everyone else in the gallery.

To go with the countless models were collections of artwork which as an outsider I coulnt see the relevence to an Architecture degree show but they were stunning none the less - very sci fi.

The models on show had a range of technologies applied to them - predominently Dprinted with elements of lasercut acrylic. I spoke toone of the students on hand and asked about the software used to create such generative forms. They all get introductions into Rhino, Solidworks, Studio MAX - even google sketchup is used extensivly. He also explained that they build several models digitally - some for specification and also some specifically for the use of prototyping technologies. All models are brought and payed for at a little above cost.

Overall the day was great and well worth the treck accross London town to get there! The level of work - and the quality and extensiveness of the 3D prints was a great thing to witness!! Some of the aplications were questionable, such as a printed landform, but over all the applications were very generative and testament to their skills on CAD. Some of the details were very fine and bridging[from my persective] the gap between technology and art.

Labels:

3D printing,

Case Study,

CNC,

Digitising,

Feature,

General,

Installation,

Lasers,

Machining,

Paneling Tools,

Pattern,

RhinoCAM,

Software,

Solidworks,

Spraying,

tutorial

Tuesday, 25 May 2010

Rhino CAM

Our pre dawn of existance CAM application is about 50% good - it is very unforgving on even the most well built CAD models.

Anyway - I delved into Rhino CAM - a plug in for Rhino 4 and offer a free demo on their webiste. I fed it a file that has been causing Excalibur to stall for around 33 hours only to let us down again and again and crash. To my suprise it took about 30 seconds for Rhino CAM to spit out a tool path - i'll bee damned.

Unfortuantely without the right post processor its unusabable on our machine. Maybe I can faf with the Post output settings but who wants to do that on a sunny day?

Anyway, have a couple of images to feast your eyes on!

Horizonal roughing - tool path generated very quickly - but i'm sure there must be a way to select a more material friendly region...

Horizontal finishing if I remember correctly. pretty fine stepover of only 10% of tool - all the stages are pretty strait forward.

And lastly, the output G code.

Anyway - I delved into Rhino CAM - a plug in for Rhino 4 and offer a free demo on their webiste. I fed it a file that has been causing Excalibur to stall for around 33 hours only to let us down again and again and crash. To my suprise it took about 30 seconds for Rhino CAM to spit out a tool path - i'll bee damned.

Unfortuantely without the right post processor its unusabable on our machine. Maybe I can faf with the Post output settings but who wants to do that on a sunny day?

Anyway, have a couple of images to feast your eyes on!

Horizonal roughing - tool path generated very quickly - but i'm sure there must be a way to select a more material friendly region...

Horizontal finishing if I remember correctly. pretty fine stepover of only 10% of tool - all the stages are pretty strait forward.

And lastly, the output G code.

Digital Terrain Modeling

Using Digimap and Rhino 3D, Bournemouth Chine was milled from Birch ply.

and

and

The model is used as reference for Nathen's 3rd year BA Hons Architecture project, the rejuvination of a bridge.

and

and

The model is used as reference for Nathen's 3rd year BA Hons Architecture project, the rejuvination of a bridge.

Labels:

Case Study,

CNC,

Digitising,

Feature,

Machining,

Rhino,

RhinoCAM,

Software,

tutorial

Two sided milling appears to be working!

Tuesday, 18 May 2010

Yes pelase

Labels:

3D printing,

Case Study,

CNC,

Digitising,

Feature,

Installation,

Pattern,

Software

Subscribe to:

Posts (Atom)